Vision, Mission, Values

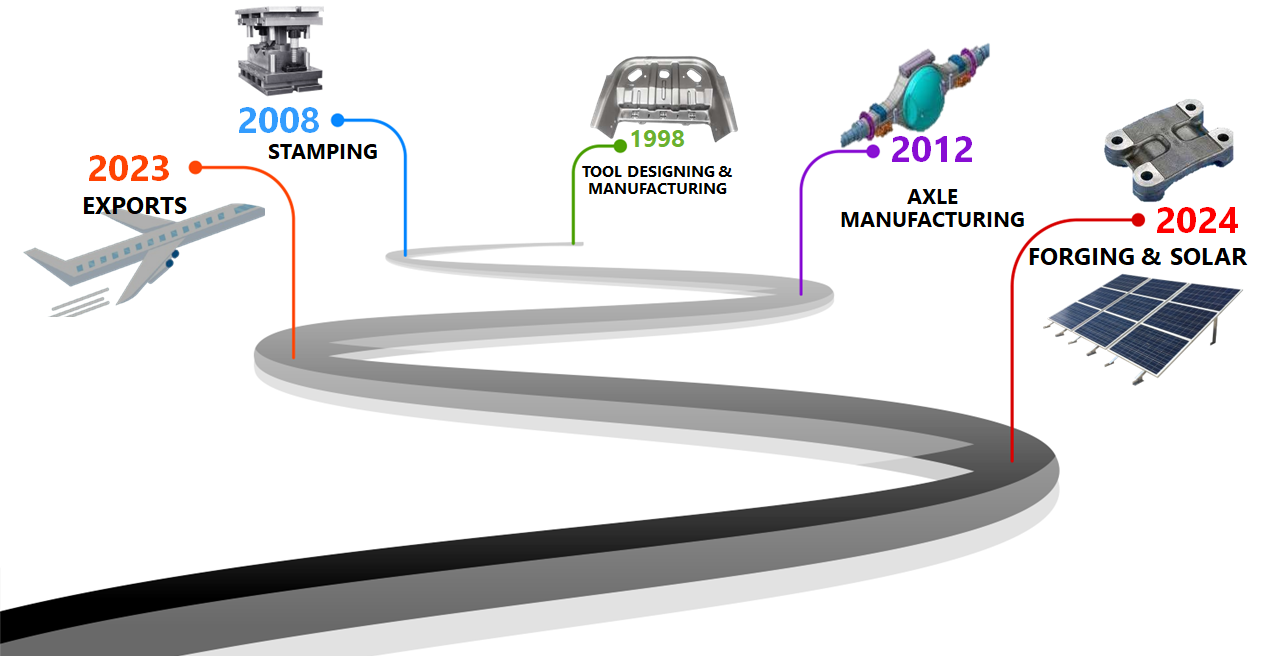

The vision is to transform the company from an auto component supplier to an engineering company with diverse complementary businesses in new high growth sectors.

VISION

Drive Technology to lead innovation across horizons by focusing on People and Environment.MISSION

Partnering our Customer to make difference.VALUES

▣ Growth ▣ Integrity ▣ Sustainability ▣ Innovation